Oulun Energia is the leading energy company in Northern Finland, offering energy services and cleaner energy for homes, companies, and society. Founded in 1889, the company employs about 300 energy professionals and covers the entire energy value chain, as well as various related services such as network management, contracting, and maintenance.

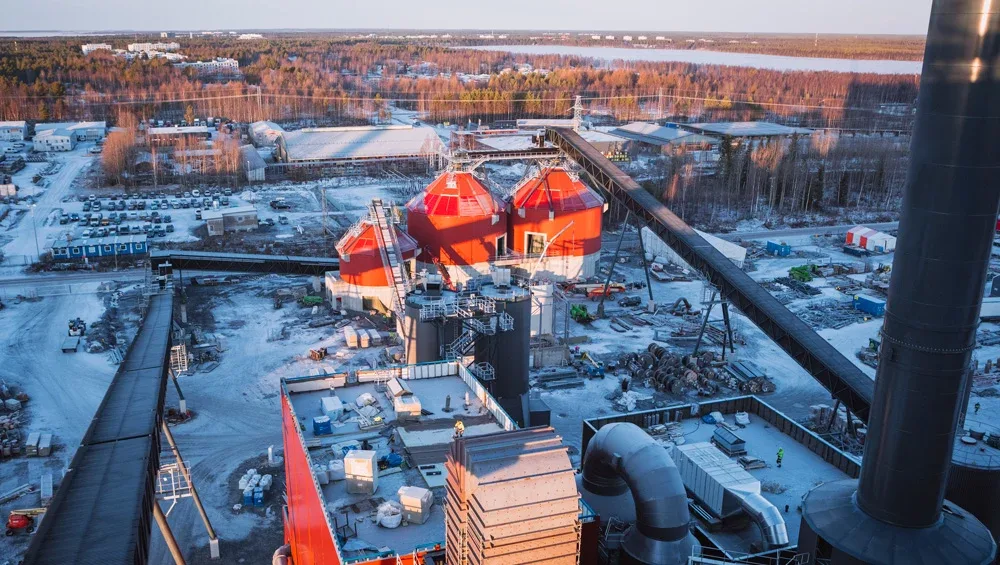

The company built a new 215-megawatt bio power plant in the Laanila industrial area. It is located in the vicinity of the eco power plant that processes waste into energy and was commissioned in 2012. The new bio power plant will significantly increase the company's share of renewable energy and support its goal of achieving carbon neutrality in its production in year 2035.

The bio power plant, which was commissioned in November, replaced the Toppila 1 power plant unit that did not meet the new environmental requirements for 2020 and was decommissioned in the summer.

District heating, electricity, and process steam for industrial needs

The Laanila bio power plant is a cogeneration plant that produces district heat and electricity. The plant will also have the readiness to produce process steam for industry needs in the future. In the new bio power plant, heat is recovered from flue gases as accurately as possible. The power plant's emissions are well below the limits set by the EU.

The project cost was approximately EUR 215 million and was one of the largest investments in the Oulu region for a long time. In the future, biorefineries or other industries using power plant steam may be integrated around the plant.

The bio power plant received an environmental permit in December 2017. Its engineering began in January 2018, and construction started in June. At the highest point, there was more than 500 people working on the site.

The circulating fluidized bed boiler utilizes versatile fuel compositions

Insta carried out the instrumentation installations for a boiler plant supplied by Valmet. Insta is the leading supplier of boiler instrumentation in the Nordic countries and has built boilers together with, for example, Valmet, Andritz, Sumitomo, Steinmüeller, and Hitachi.

In a multi-fuel boiler utilizing circulating fluid technology, versatile fuel compositions can be burned, and their ratios easily changed. The goal is that about 70 percent of the fuel used for the plant is wood. The remaining 30 percent consists of recycled fuel from the circular economy (15) and peat, which ensures the security of supply (15). The use of peat will be reduced and phased out.

Insta's share in the project began in October 2019 and lasted until May 2020. The site had a maximum of 14 employees.

In addition to its local site in Oulu, Insta utilized the resources and unique expertise in Tampere and other sites.

– Insta is a familiar and reliable, long-term partner for Valmet, explains Valmet's project manager Jukka Lehtinen.

– The cooperation was effortless. The schedule was adhered to, and the engineering was well done. As a result, the additions and changes during installation also went smoothly, Lehtinen sums up.

Picture: Kati Leinonen